* I participated in a campaign in behalf of Mom It Forward Blogger Network for McDonald’s. I attended an event to facilitate my review and though I was compensated for this campaign, all opinions are my own.

I felt like an excited school kid going on a field trip when I was invited and got the chance to join the annual McDonald’s Field to Restaurant Tour. The yearn to learn and discover the “behind the scenes” is what really made this trip more interesting.

Breakfast

Our call time is at 8am at a McDonald’s branch in San Jose. It is a good thing that I just live nearby and was able to get there on time. There I met the McDonald’s PR Team, some Bay Area McDonald’s Franchise Owners, a number of local press people and of course some blogger friends (happy dance!).

After checking in, I ordered breakfast where I had Bacon and Egg with Cheese McGriddle plus my favorite Sweet Tea. We were given ample time to have a little chat with the other participants of the tour before heading off to Salinas, CA where the Chiquita Fresh Easy facility is located.

While aboard the bus, Steve Peat, a franchise owner of several McDonald’s branches in the Bay Area gave an overview of the day and background on McDonald’s offerings and suppliers. He is a member (together with the other franchise owners who went on the tour) of the Greater Bay Area McDonald’s Cooperative which is comprised of individuals who own and operate more than 248 McDonald’s restaurants in the 15-county Bay Area region.

Chiquita Fresh Express Facility

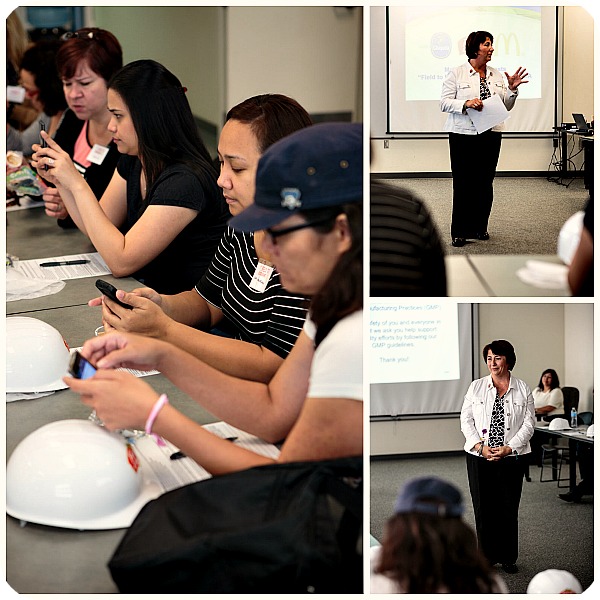

We were welcomed by Kathie Baka, Chiquita Brands Supplier Quality Support (McDonald’s Account).and Nanu Menon, Chiquita Brands Director of Supply Chain (West Region). Kathie gave us an overview of the existing partnership between McDonald’s and Chiquita Fresh Easy in delivering quality products to us consumers.

The Chiquita Fresh Easy facility in Salinas is one of the three main facilities that supply apple products to McDonald’s all across the country. They have continuous production to provide the need for apples on McDonald’s stores.

The Plant Tour

The Chiquita Fresh Easy Facility operates under quality standards. It has GFSI (Global Food Safety Initiative) FSSC (Food Safety System) 22000 Certification which means that it passed the global requirement for food safety and can be trusted by consumers in the supply of food and drinks. Keeping hygiene at the highest level is one of the most important things a food facility can do, as well as ensuring all equipment like work tables, fridges, and sinks are up to code. This information assured me that this plant is reliable in terms of cleanliness and hygiene. My cousin in the UK who owns a restaurant business tells me that they have similar food hygiene regulations. Professional services like https://www.sentientuk.co.uk/food-hygiene/ are of great help in being compliant with the food safety standards.

Temperature plays a vital role, it is always the key to preserve freshness. With that, we needed jackets to survive the 32 degrees temperature inside the plant. Jewelries and accessories were prohibited inside the production area as well as gadgets in order to maintain safety. In addition, we were required to wash our hands before putting on our “gears”and sanitized our boots before entering the processing area.

Just like any processing facility Chiquita Fresh Easy practices strict GMP (Good Manufacturing Practices) and so we were asked to put on the standard plant uniforms : hairnet (plus beard net for guys), hard hat, white production gowns, no-slip boots, disposable latex gloves, ear plugs (protection against the loud sound coming from the machines) and plastic sleeves.

The Chiquita Fresh Easy Facility produces 16 SKU’s (Stock Keeping Units) in lay man’s term “items” for McDonald’s. We specifically viewed the production of McDonald’s Apple Slices, one of the most popular snack items in Happy Meals and the McDonald’s Diced Apples which is served with the Fruit & Maple Oatmeal.

I am a Food Science major, and so the plant tour brought back memories of the days when I worked as Quality Assurance Analyst and my enthusiasm for the processes involved in the production. From the photo below, we will see how a raw apple travels in a conveyor through out the whole process : washed, peeled, cored, sliced or diced then packed. The apple comes out packed and ready to be boxed. The packaging has the usual product codes which can make tracing a bit faster in the event of a recall or problem with the product.

As you might be asking : What happens to the peel, core and trimmings removed from the apples? Well, they are used to make animal feed. The apples were subjected to water with only ascorbic acid, much similar to the role of lemon juice to prevent discoloration. Quality Control is practiced with the intervention of plant workers segregating the pieces which does not conform to standards.

It is undeniable that there are tons of water used in the whole process of cleaning and processing of the apples and as we were informed by the plant manager, the facility has its own water recycling treatment process so no water is wasted.

Seeing how the plant operates in such a hygienic and sanitized environment gives me confidence in the products they serve at McDonald’s. I was also told that all employees have to complete food hygiene training online too. It was all so clean and professional! It is possible that my own kitchen has more contaminants as compared to the controlled environment of the plant.

Chiquita Fresh Easy uses Raw Sourcing, which means that scale and regional supply ensures continuity, it has the ability to serve fresh produce in short load times. To explain, the fruits come in fresh and processed in a minimal time to retain its freshness.

This opened my eyes to the fact that McDonald’s (contrary to what most believe) serve fresh and care for better nutrition and health.

In fact, McDonald’s customers in the U.S. have also enjoyed around 200 million cups of fruit between August 1, 2012 and July 31, 2013 from menu options like Fruit n’ Maple Oatmeal, Fruit ‘n Yogurt Parfait and apple slices. There have been 530 million individual packages of apple slices served with a children’s meal between August 1, 2012 and July 31, 2013.

Soon after the plant tour, we headed to Fresh Easy research and innovation center where a lunch was prepared by two amazing guest chefs. They put together a sumptuous lunch using McDonald’s ingredients.

Please check out The Lunch, Part Two of the McDonald’s Field to Restaurant Tour.

I love that McDonald’s works with Chiquita {who has very high standards of quality}. It’s nice to hear that the trimmings don’t get wasted either 🙂

How fun, that’s pretty neat to see the process!

As much as I like to cook homemade meals, with rushing to soccer, school functions, etc. it can get a little hectic. It’s good to know that there are ways to increase the nutrients.

32-degree, aaaaaaagh. Besides that (cold temperatures) everything sound really nice!!

I love that fast food companies, including McDonalds, have increased menu items consisting of real foods. It is always fun to watch how real, healthy, nutritious foods are processed so we can all benefit from them!

I love seeing the behind the scenes look at where the food comes from. We love the apple slices from McDonald’s. So nice to see the high standards of processing them.

I like some transparency to companies, especially when it comes to food. I’m happy to see they are giving plant tours! Chiquita looks like they have high standards!

I have to admit that McDonalds is not really for me BUT I wasn’t aware of these facts so a big plus and something new I learned today 🙂 Thanks for that!

same thing with me, I had different notions before but things change when you learn something…

Thanks for sharing this experience. It is nice Mcdonalds offer healthy food and how much calories are in it.

I would love to be able to go on a tour like this. My kids love Mc Donalds.

What a cool opportunity! I always love posts that take me behind the scenes of my favorite places. Thanks!

This is so cool! Going ‘behind the scenes’ must have been quite an experience. It’s interesting to know that McD’s actually serve fruit with their Happy Meals – something we don’t have here in the Philippines. I read somewhere in the internet that Happy Meal toys will soon be replaced by books? I like that idea and I hope they bring it here to the PH, too. 🙂

Wow! Didn’t know McDonald’s have that. They do that annually? Looks fun and informative at the same time 🙂

Yes they do! I sure did enjoy this activity and hope to be invited again next year…its is indeed very informative to be able to know what processes a product undergoes before it is being served at stores…